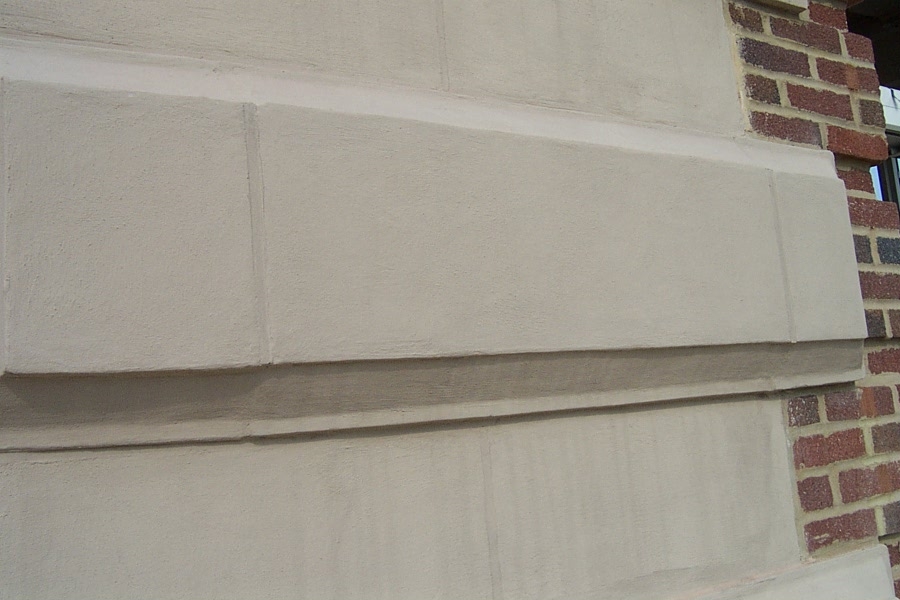

Matrix TR is formulated to provide long-term protection of natural stone and concrete when full-depth repairs are unnecessary or not practical.

Where to use:

Thin, protective repairs to brownstone, sandstone, limestone, cast stone, terracotta, and concrete.How to apply:

Brush or trowel applied. [expand title=”Additional Information” swaptitle=”Minimize Information”]Performance Characteristics

- Low shrinkage Maintains integrity of repair, resists cracking.

- Thermal compatibility Prevents delamination due to temperature change.

- Durable Resistant to weathering action, excellent freeze/thaw stability and abrasion resistance.

- Very low permeability Resistant to deicing salts, carbonation, chloride, and chemical attack.

- Breathability Will not cause damage to structure by restricting moisture vapor flow.

- Complete kit Pre-measured, two component system in one container.

- Extensive color spectrum Available in 11 standard colors and custom color matching.

Surface Preparation

- Remove loose and deteriorated material, laitance, dirt, dust, oil and any surface contaminants that will inhibit proper bond.

- Apply Conpro Start where a consolidant is of benefit.

- Pre-treat static cracks and voids with Injection Grout where applicable.

- Saturate substrate with clean water, (saturated surface dry/SSD).

- Mechanically prepare surface to be open-pored and textured (CSP 3). Refer to ICRI Surface Preparation Guide 03732 for information about surface preparation.

Priming

- No priming is required under normal circumstances.

Mixing

- Mechanically mix using a low speed drill (400-600 rpm) and mixing paddle.

- Thoroughly shake K-88 Admix to disperse the pigment.

- Mix 3 parts powder to 1 part K-88 Admix.

- Mix continuously for 3 minutes to a uniform, lump-free consistency.

- Allow to “breathe” for 1 minute and remix for 1 minute. This will improve workability and open time.

- Do not overmix, as this will entrain excess air.

- Do not re-temper.

Application

- At the time of application, surfaces should be saturated surface dry (SSD) but hold no standing water.

- Apply material with a stiff bristle brush or trowel.

- Work material into substrate to promote proper adhesion.

- Coat individual stones (not continuous over mortar joints) a maximum thickness of 1/16 inch.

- Finish with either a sponge float or trowel.

- Do not overwork the finish.

Curing

- Protect repair from direct sunlight, wind, rain condensation and frost during curing period.

Clean Up

- Clean tools and equipment with water immediately after use.

- Cured material must be removed mechanically.

Coverage/Yield

- 10 lb. kit – 20 ft² @ 1/16 inch.

Product Handling

- Packaging 10 lb. kit contains 8.36 lbs. of powder and 2.1 lbs. of K-88 Admix in plastic pails.

- Shelf Life 18 months when properly stored.

- Storage Transport and store in cool, clean, dry conditions in unopened containers. High temperature or high humidity will reduce shelf life. Protect K-88 Admix from freezing.

Limitations

- Do not apply unless substrate and ambient temperature can be maintained at a minimum of 50°F for 24 hours. Refer to ACI Cold Weather Application Guidelines.

- Protect application from precipitation condensation and high wind for at least 24 hours.

- Do not re-temper, polymer modified materials.

- Avoid overworking material during placement.

- Do not apply curing compounds.

- Do not allow polyethylene or burlene to touch surface while curing as this will cause whitening of the material.

Health and Safety

- Product is alkaline.

- Do not ingest.

- Avoid breathing dust.

- Avoid contact with skin and eyes.

- Refer to Safety Data Sheet (SDS) for additional information.

First Aid

- In case of skin contact, wash thoroughly with soap and water.

- For eye contact, flush immediately with a high volume of water for at least 15 minutes and contact a medical professional.

- For respiratory problems, remove person to fresh air.

Disposal

- Dispose of material in accordance with local, state and federal regulations.